Centrifugation – the basics

A centrifuge produces a centrifugal force many times greater

than the earth’s gravity, by spinning

the sample about a central axis.

Centrifugation is the

process of separating mixtures suspended in a liquid by applying centrifugal force.

A very slow centrifuge….

A rather faster centrifuge…

Particles of different size, shape, or density will sediment at different rates, depending

on the speed of rotation and distance from the central axis.

Centrifugal field G, operating on a particle P, spinning at

a distance r from the central axis of a centrifuge.

Centrifugal force

Is centrifugal force real?

For our purposes:

Centrifugal force acts in an outward direction when a

particle or object moves in a curved or circular path.

Exploded view of a centrifuge

A centrifuge:

a piece of equipment that rapidly spins a number of tubes

which contain a suspension of particles in a liquid

A typical centrifuge

The force which causes particles to move down in a

centrifuge tube:

Applied Centrifugal Field

• G = ω2 x r [ω

is the Greek omega]

• where

G is the applied centrifugal field (in cm per second squared: units of

acceleration)

• ω is the angular velocity of the rotor (in radians per second)

• r is the radial distance of the particle from the axis of rotation (in

centimetres)

Applied Centrifugal

Field and revolutions per minute

(revs.)

• The

angular velocity ω is more easily understood in terms

of revolutions per minute:

• ω = 2π

x (revolutions per

minute) / 60

• Therefore

since G = ω2 x r, the applied centrifugal field becomes:

• G = 4π2 x r x (revolutions per minute)2 / 3600

Equation to apply

for G in cm/s2

A pilot

in a fast aircraft executing a sharp turn or climb will experience a ‘g force’

several times that of gravity.

We can

also express Applied Centrifugal Force in a centrifuge as a ‘g force’

Relative Centrifugal

Field (RCF)

• The

centrifugal field is more commonly expressed in multiples of the gravitational

field of the earth (981 cm per second squared)

• Known

as the Relative Centrifugal Field (RCF)

and the units are in g:

• RCF = 4π2 x r x (revolutions per

minute)2

/

(3600 x 981)

• This

simplifies to

Relative Centrifugal Field (RCF) =

1.118 x r x

(revolutions per minute)2 x

10 -5

[ where the radius r is in centimetres (cm)]

1g = 981cm/s2

Equation to apply for RCF units of g

Applied and Relative Centrifugal Field

• The Applied Centrifugal Field G G= 4π2 x r x (revolutions per minute)2 / 3600

[in units of cm per second squared]

• and the Relative Centrifugal Field (RCF)

RCF=

1.118 x r x (revolutions per

minute)2 x 10 -5 [in

units of multiples of gravity]

[NOTE: G = RCF x g]

[the radius r is in centimetres (cm)]

Relative Centrifugal

Field (RCF)

QUESTION:

• A

fixed angle centrifuge spins at 20 000 revolutions per minute. The distance from the centre of the liquid

suspension in the centrifuge tube to the axis of rotation is 35 mm. What is the Relative Centrifugal Field

experienced by the particle?

• RCF= 1.118 x r x (revolutions per minute)2 x

10 -5

Example: calculation

of RCF

• Spins

at 20 000 revolutions per minute.

Distance from the centre of the liquid to axis of rotation is 35 mm (remember

to convert this to centimetres = 3.5 cm).

RCF = 1.118 x r x (revolutions per minute)2 x

10 -5

• RCF = 1.118 x 3.5 x (20000)2 x 10 -5

• = 1.118

x 3.5 x (4 x 108) x 10 -5

• = 1.118 x 3.5 x 4 x 103

• RCF = 15652 g [where g means

times the force of gravity]

Nomogram

Columns are (left to right): Radius (cm); RCF (g); Speed

(rev/min)

The

line gives an RCF of 100,000 or 1000g for a centrifuge radius of 10 cm and

speeds of 30,000 and 3,000 rev/min respectively.

Types of centrifuge

• Low-speed

centrifuges Swing-out rotors are

used in low-speed centrifuges (3000-6000 r.p.m.) for harvesting cells and

larger organelles (e.g. nuclei).

• Microcentrifuges Fixed-angle

rotors are used (up to 12 000 r.p.m) for higher-speed operation, for cells and

precipitates.

• Ultracentrifuges (speeds

greater than 30 000 r.p.m.) are used for very small particles e.g. biological

macromolecules.

Swing-out low-speed centrifuge and sample tube

Swing-out

centrifuges are used at speeds of 4000-10000 revs. per minute, with RCFs of

3000 – 7000g.

Mainly

used to collect material that sediments rapidly

eg PEI

resin from HCl

Table-top microcentrifuge

One of the most commonly used centrifuge types. Can reach

speeds of 12000-15000 rpm (RCF about 12000g).

Mainly

used to harvest small volumes of cells, or isolate microgram quantities of (for

example) proteins and nucleic acids.

Microcentrifuge has a fixed-angle rotor and uses

microcentrifuge tubes

Eppendorf’ tube

capacity 1.5ml

Smaller (0.5 ml or 0.2 ml) tubes require use of different

rotors

Floor-standing large centrifuge

For

centrifuging large volumes of a mixture at one time.

Centrifuge for 96-well plates

An ultracentrifuge

Ø Refrigeration

Ø Operates

under vacuum

Ultracentrifuges

• Refrigeration

is needed to counteract the heat generated during centrifugation at high speed,

to keep clinical and biological specimens stable.

• Evacuation

also reduces air friction.

• Analytical

centrifugation uses an ultracentrifuge with an optical system to observe the

settling of the particles.

Different types of centrifuges

Rotor types

Centrifuge with swing-out rotor

When

the rotor is in motion and the tubes are horizontal, why doesn’t the liquid

drain away?

Angled rotor

This is

the type most often used with microcentrifuge tubes. Another version is used

with very high speed centrifuges

Solid

construction; heavy; sample tubes have tops fixed in place during spinning.

Fixed angle rotors

• Are

ideal for pelleting during differential centrifugation to separate biological

particles with different sedimentation rates.

• The

pellet is the name given to the material which collects at the bottom of the

centrifuge tube. The liquid left above the pellet is the supernatant.

Vertical rotor

Ø Vertical

rotors use sealed centrifuge tubes

(diagram is not accurate!). Why?

Ø Samples

sediment across the diameter of the tube – short run times.

Centrifuge: application at UEL

Sample preparation for HPLC high performance liquid

chromatography:

example

Analysis of herbal

medicine tincture solutions and dried plants for active ingredients

HPLC column. Can be blocked by small particles. Remedy:

microcentrifuge the sample solutions before analysis and use the clear solution

above the pellet for analysis.

Centrifugal force

Centrifugal force acts in an outward direction when a

particle or object moves in a curved or circular path.

A centrifuge is a piece of

equipment that rapidly spins

a number of tubes which contain

a suspension of particles in a liquid

Sedimentation

Sedimentation

is the settling of solid particles through a liquid under the influence of a

gravitational or centrifugal field.

The speed at which a particle will settle in a liquid is

related to the size, shape and density of the particle.

The size of the particle is the major

determining factor in the settling (or sedimentation) rate of a particle, but

its density and weight also make a difference to the speed.

Sedimentation of different-sized particles

Factors controlling the sedimentation of a particle

• The

denser a particle, the faster it will sediment

• The

heavier the particle, the faster it will sediment

• The

denser the solution in which it is suspended, the slower a particle will

sediment

• If

the particle and solution are of equal density the particle will not sediment

• The

greater the centrifugal force, the faster it will sediment

Sedimentation and particle size

Particles

of different sizes can be separated by the difference in their sedimentation

rate.

Centrifugation

is a convenient method of increasing the speed of sedimentation of all the

particles in a mixture.

• But

the relative rates of sedimentation of different size particles are not

affected by the speed of the centrifuge.

• For

example if particles of size A sediment ten times faster than those of size B

at 1000 revs per minute (centrifuge speed), A also sediments 10 times faster

than B at 10,000rpm.

Rate of

sedimentation

• The

rate of sedimentation of a

particle in a solution (medium) is given by Stoke’s Law:

V= 2 x R 2 (ρp - ρm)

x g x RCF

9 η

• V

= sedimentation rate in cm per second;

• R is the radius of the particle in cm;

• ρp and ρm are the densities of

the particle and medium (solution) in gm/cm3

• g is the gravitational field in cm/sec2,

which should be multiplied by the Relative Centrifugal Field (RCF)

• η is the viscosity of the medium

(units are gm/sec.cm).

• V= 2 x

R 2 (ρp - ρm) x g x RCF

• 9 η

• where V = sedimentation rate in cm per second

• QUESTION: what if ρp and ρm are equal?

• - the densities of the particle and the medium

(the solution).

calculation of rate

of sedimentation

V= 2 x R 2 (ρp - ρm)

x g x RCF

9 η

• For

a particle of radius R

0.02 cm (diameter 400

microns) [1cm=10mm=10,000microns]

• particle

density ρp of 1.2

gm/cm3 in a liquid of density ρm 1.0 gm/cm3

• liquid

viscosity η of 1.00

• g=

980 gm/cm2 in a centrifugal field with RCF=1000g:

What is the Sedimentation rate (v) in cm/sec?

V= 2 x R 2 (ρp - ρm)

x g [1cm=10mm=10,000microns]

9 η

• Particle

radius R 0.02 cm (diameter 400 microns)

• particle

density ρp of 1.2

gm/cm3 in a liquid of density ρm 1.0 gm/cm3

• liquid

viscosity η of 1.00

• g=

980 gm/cm2 in a centrifugal field with RCF=1000:

Sedimentation

rate (v) is calculated as

• =

2 x (0.02)2 x (1.2 – 1.0) x 980 x 1000 /( 9 x 1)

• =

2 x 4 x 10-4 x 0.2 x 980 x 1000 / 9

• =

17.42 cm/sec

We may wish to calculate not the rate of sedimentation (in

cms per second), but the time taken for a particle to settle – this is more

useful to know.

Distances needed to calculate time for a particle to settle :

rt (radial distance to top of liquid)

rb (distance to bottom of tube)

Settling out time for a particle

t = 9 x η x (ln

rb/rt) x 3600

8 π2 (ρp - ρm) (rev/min)2

x R2

η is the

viscosity of the medium (units are gm, sec and cm).

rb and

rt are

the radial distance to bottom and top of liquid

ρp and ρm are the densities of

the particle and medium (solution) in gm/cm3

R is the

radius of the particle in cm;

Centrifugation

is used for two main applications: Preparative

and Analytical

Preparative is the separation of

components of cells etc into their components

Analytical produces information

on the quantities of components present.

Preparative also divides

into two types: 1) Differential

(this week) and

2)

Density gradient (next week).

Preparative centrifugation

1. Differential

Centrifugation

• uses

differences in sedimentation rate

• selectively

sediment out particles with particular properties

• applied

centrifugal field is increased step-wise

• at

each stage different types/sizes of particles can be collected

Differential centrifugation

The

longer a solution is centrifuged, the more the particles separate by size.

In

Differential centrifugation, the centrifuge is run for long enough for all the

particles of a certain size to pellet out, leaving the smaller sizes suspended

in the supernatant.

Differential centrifugation: separates into different

particle sizes

• Largest

particles separate out first (into the pellet)

• A

suspension of particles is centrifuged just long enough to pellet the largest

types.

• The

supernatant liquid is poured off into another centrifuge tube.

• But

some small particles also ended up in the pellet. What to do about it?

Sedimentation – getting clear separation into particle sizes

• Particles

of small size ‘trapped’ in the pellet.

• Answer:

remix the pellet with liquid to get another suspension; re-centrifuge until all

the large particles are in the pellet.

• After

this second stage, an even smaller number of small particles are ‘trapped’.

• The

supernatant liquid is added to the first supernatant liquid for centrifuging

out the next (smaller) size particles.

A useful rule for differential separation:

It has

been shown in practice:

to

achieve an effective separation between particles of two different sizes, they

must differ by an order of magnitude

ie –

one must have a diameter 10 times that of the other.

Angled rotor

Sedimentation patterns in different

centrifuge

rotors

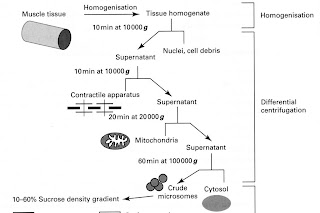

Practical example of Differential centrifugation

Differences

in sedimentation rate are used to selectively sediment out particles with

particular properties: example - fractionation of skeletal muscle homogenate. (see K.Wilson and J.Walker, Principles and Techniques of Practical

Biochemistry)

•

applied centrifugal field is increased step-wise

•

at each stage different types/sizes of particles

can be collected.

Example of a step-wise separation of a skeletal muscle

homogenate

Differential centrifugation Stage 1

• centrifuge

the mixture of 10% (w/v) of the

homogenate at 1000g (RCF) for 10 mins: pellet = cell nuclei plus debris

Differential centrifugation Stage 2

supernatant

from stage 1 is then re-centrifuged at 10,000g for 10 min; pellet = contractile apparatus.

Stage 3

supernatant from 2 re-centrifuged

at 20000g for 20 min; pellet = mitochondria

Stage 4

• supernatant

re-centrifuged at 100 000g for 60 min; pellet = crude microsomes; supernatant contains cytosol. [ultracentrifuge required]

• Ribosome from E.Coli.

• [Microsomes

are rich in ribosomes]

Centrifugation

is used for two main applications

Preparative

and Analytical.

Preparative

is the separation of components of cells etc into their components.

Analytical

produces information on the quantities of components present.

Preparative

centrifugation

also divides into:

1:Differential

The

centrifugation field is increased in stages.

2:Density gradient

- Rate

zonal (particle size separation)

- Isopycnic

(particle density separation)

1: Differential centrifugation

Differential

Centrifugation uses differences in sedimentation

rate to selectively sediment out

particles of different sizes.

BUT: Differential

Centrifugation is not very good at separating particles which are only slightly

different in size.

2:Density gradient

centrifugation

divides into:

- Rate

zonal (particle size separation)

- Isopycnic

(particle density separation)

What is density gradient centrifugation?

In Density

Gradient centrifugation, the density of

the solution in the centrifuge tube increases from the top to the bottom

of the solution.

2: a. Density

Gradient

RATE ZONAL centrifugation

• Particles

are separated by size

• Different

sizes of particles move at different speeds down through the density gradient.

- RATE

ZONAL centrifugation is like a race: the particles travel at different

speeds towards the bottom of the centrifuge tube. Their size controls

their speed.

- Particles

which differ is size by 10% or more can be separated.

RATE ZONAL

centrifugation:

how it works

- layer

a mixed sample in solution onto the top of a shallow pre-formed density

gradient

- centrifuge

- larger

particles will move faster through the gradient than the smaller

- distinct

zones (bands) of different size particles

- Centrifugation

is stopped before any band reaches the bottom of the tube.

2: Density Gradient

RATE ZONAL (particle size separation) – THEORY

If two

types of particle are very similar in density, but of different mass (that is,

radius, or size) the two types will sediment at different rates.

Sedimentation rate (Stoke’s Law) depends on

the radius squared (R is the radius):

V= 2 x R 2 (ρp - ρm)

x g x RCF

9 η

Rate-Zonal Density Centrifugation

• The

density gradient does not change very much down the tube

• Antibody classes all have very similar

densities, but different masses.

Separation based on mass

will separate the different classes, but separation based on density will not be able to resolve

these antibody classes

Criteria for

successful rate-zonal centrifugation

• Density

of the sample particle must be greater than that of the highest density portion

of the gradient

• The

pathlength must be enough for separation to occur

• Time

is important. Too long a run, and all

particles may pellet at the bottom of the tube.

Rate-zonal centrifugation

2: b. Density

Gradient ISOPYCNIC centrifugation

If a

particle and solution are of equal density the particle will not sediment.

Samples

are added to solutions in which the liquid density increases towards the bottom

of the centrifuge tube (and the solutions are then centrifuged).

Isopycnic

density gradient centrifugation

• Isopycnic

(from the Greek: isos: equal, pyknos: dense)

• Requires

a steep density gradient (the density increases fairly rapidly down the

centrifuge solution)

• During

centrifugation, once a particle reaches a part of the solution with the same

density as itself, it will not sink further.

Equilibrium Isopycnic density gradient centrifugation

Rate Zonal vs

Isopycnic density gradient centrifugation

2: Applications of density gradient centrifugation

• where

there is more difficulty in separating out a mixture – for example where there

are several kinds of large molecules or particles which must be separated from

one another.

• to

obtain fractions enriched in individual proteins from the supernatant obtained

from a low-speed centrifugation of broken cells.

• for

separation of protein molecules, high rotor speeds (often up to 70000 rpm) are

required.

Solutions used in forming a density gradient

Sucrose - a sugar

Glycerol

Ficoll – a polysaccharide

Percoll – a colloidal silica

Caesium Chloride – an alkali metal salt Disadvantage: may

damage biological structures

Density gradient types

for either Rate-Zonal or Isopycnic

Methods of forming density gradients

With a special mixing instrument

(will form linear, concave and convex gradients).

Or

A self-forming gradient (a

solution which forms a gradient just by centrifuging it).

Percoll will spontaneously form a LINEAR gradient when a

solution is centrifuged

Percoll solutions

contain colloidal silica particles coated with a thin layer of plastic. Centrifuging a solution will spontaneously

form a LINEAR gradient –known as a self-forming gradient. The Percoll colloid

settles to the bottom of the tube, making the solution denser from the top to

the bottom

Laboratory practical

is on isopycnic density gradient

- A

gradient has been pre-formed in a centrifuge tube using Percoll

- Carefully

pipette/layer the density marker beads (coloured) on top of the Percoll

solution

Laboratory practical: isopycnic density gradient

- Centrifuge

the solution. The beads will settle in coloured layers. Each colour

represents one density.

- Measure

the distance that each coloured layer has moved from the top of the

solution.

Rf = (distance

travelled by a layer of beads/total distance)

distance travelled

by a layer

total distance

Analytical

Centrifugation

Analytical produces

information on the quantities of components present.

It usually requires the use of

an ultracentrifuge – high speeds are required.

A spectrometer is used to

monitor changes in the optical absorbance of the solution as the particles

sediment.

Uses of analytical centrifugation

• Determination

of the purity of macromolecules

• Determination

of the Relative Molecular Mass of molecules in solution

• Changes

in Relative Molecular Mass of molecules

• Study

of the binding sites (receptors) on proteins for cell signalling

Analytical rotor and absorption cell

Analytical ultracentrifugation

Analytical

centrifugation:

measuring changes in optical characteristics.

The rate of movement of a concentration boundary gives information on the

biomolecule.